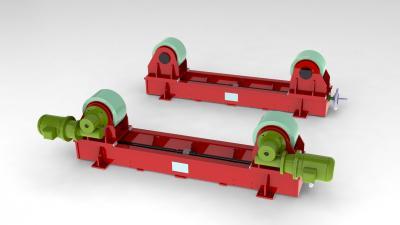

Plate to Plate Seamers

5050000.00 INR/Piece

Product Details:

X

Plate to Plate Seamers Price And Quantity

- 5050000.00 INR/Piece

- 2-3 Piece

Plate to Plate Seamers Trade Information

- 50 Piece Per Month

- 30-45 Days

- Wooden Packing

- All India

Product Description

The Huaheng Automation Pvt. Ltd. Company is located in Vadodara, Gujarat, India, engaged as a Supplier and Manufacturer of Plate to Plate Seamers. We have a team of well-experienced professionals, all the products are made under their supervision, by using the top-notch quality raw material and ultra-modern techniques. Furthermore, the range of Plate to Plate Seamers offered by us at an affordable price.

Shell Cover Manufacturer

Features:

Features:

Features OF Plate to Plate Seamers :

- Optional to choose standard or customized mechanism according to work piece size.

- Suitable for 0.4mm-12mm wall thickness sheet welding;

- Suitable for TIG, MIG/MAG, PAW and PLASMA+TIG welding process;

- Suitable for various materials, such as carbon steel, stainless steel, titanium alloy and aluminum alloy, etc.

- Use copper made finger clamp to achieve small welding distortion and high welding quality;

Application :

Shell Cover Manufacturer

Features:

- According to the workpiece, the welding process can be PLASMA + TIG, two welding torches at same time, to realize one-side welding two-side shaping and much higher welding efficiency

- Finger clamping design to hold the workpiece, with water-cooled copper-made backing system, taking away heat from welding to the max extent possible, and realizing less workpiece distortion

- Option of real time monitor system, the operator can make the adjustment by seeing the monitor during the welding, ensuring the welding quality

- Single TIG welding process can be used when the plate wall thickness is less than and equal to 3mm

- Suitable for stainless steel, titanium alloy and so on

- Turn-key project

- Welding parameters are setting by touch screen, easy to understand and operate

Features:

- Advantages of plasma welding process, higher welding efficiency, better quality, less workpiece distortion

- Huaheng has more than ten years of Plasma application experience in terms of excellent welding process and service ability

- The specially-designed sheet to sheet longitudinal seam welding system, with single plasma torch or plasma and TIG torches, can perfectly solve issues of composite board welding

- There is no wire feeding and bevel on sheet for welding wall thickness of 3mm, 4mm, 5mm and 6mm; thus reducing the production cost. And even more cost saved by polishing process afterward

- Turn-key project

- When the wall thickness is greater 6mm, it is recommended to adopt plasma and TIG welding process, thus even higher welding efficiency,about 30% higher compared with single torch welding

Special Purpose Vehicle

Features:

- As the workpiece is large, the structure of this welding system is very rigid, capable of bearing the clamping forces. The welding torch is installed on the small kart, travelling on the beam which locates on the top of the fixture; The straightness accuracy is very well, to ensure the seam welding quality

- Huaheng has more than ten years of Plasma application experience in terms of excellent welding process and service ability.

- Touch screen interface, programmable welding parameters, easy to operate, and very stable controller

Specification :

| Model | HP3000 | HP6000 | HP8000 | HP10000 |

| Maximum welding length for single torch (mm) | 3200 | 6160 | 8160 | 10160 |

| Maximum welding length for double torch (mm) | 2700 | 5700 | 7700 | 9700 |

| Sheet wall thickness | 1.0-12 | 2.0-12 | 2.0-12 | 2.0-12 |

| Maximum single side pressure (kgf/cm) | 30 | 30 | 30 | 30 |

| Adjustable fingers distance (mm) | 10~40 | 10~40 | 10~40 | 10~40 |

| Welding trolley speed (mm/min) | 60~1200 | 60~1200 | 60~1200 | 60~1200 |

| Cushion vertical traverse (mm) | Motor driven 60 | Motor driven 60 | Motor driven 60 | Motor driven 60 |

| Dimension (LxWxH) (mm) | 6120x1200x1650 | 9200x1200x1650 | 11150x1200x1700 | 13150x1200x1800 |

| Weight (Ton) | 5.4 | 8.9 | 11.8 | 13.9 |

Other Products in 'Mechanized Welding System' category

Get in touch with us